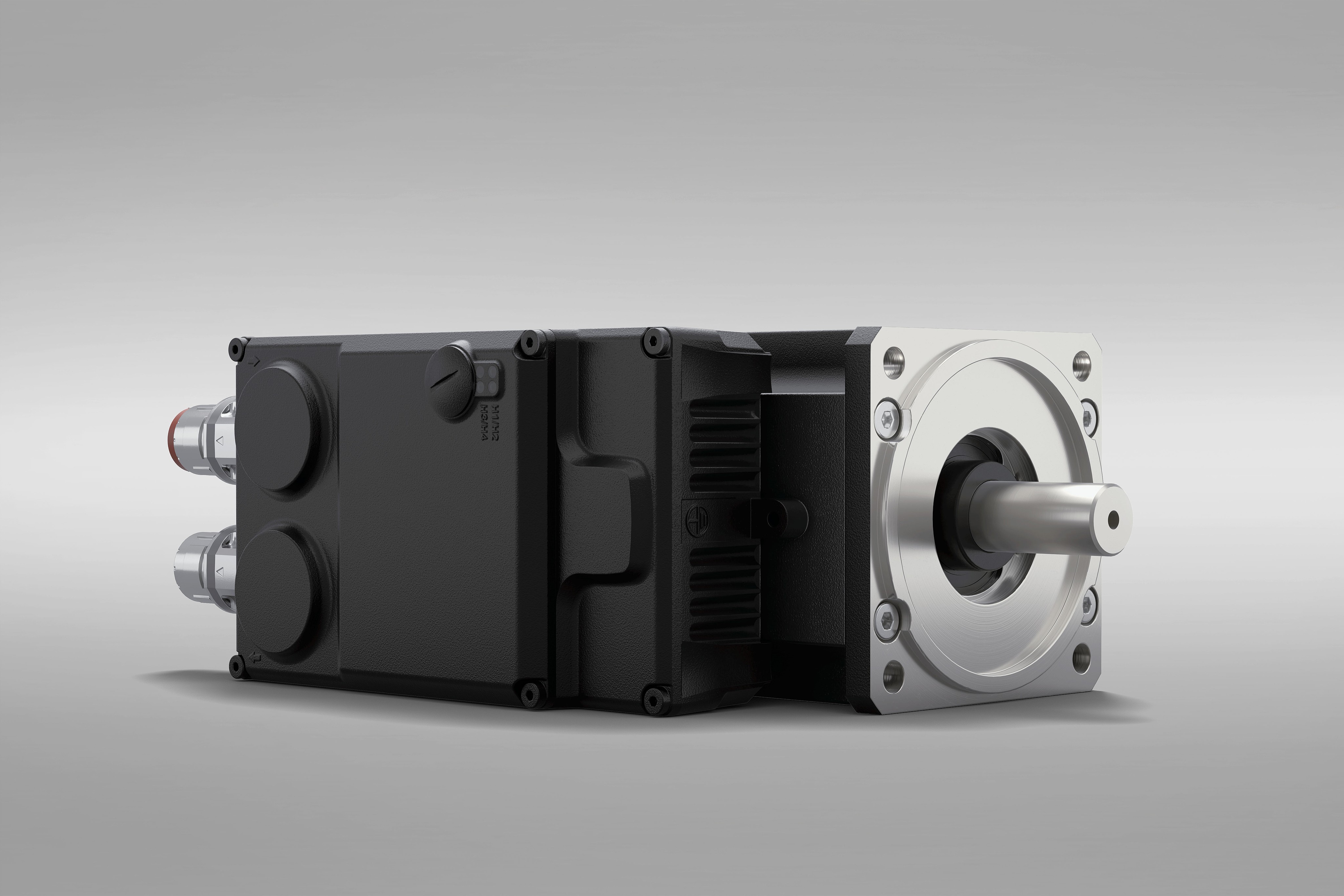

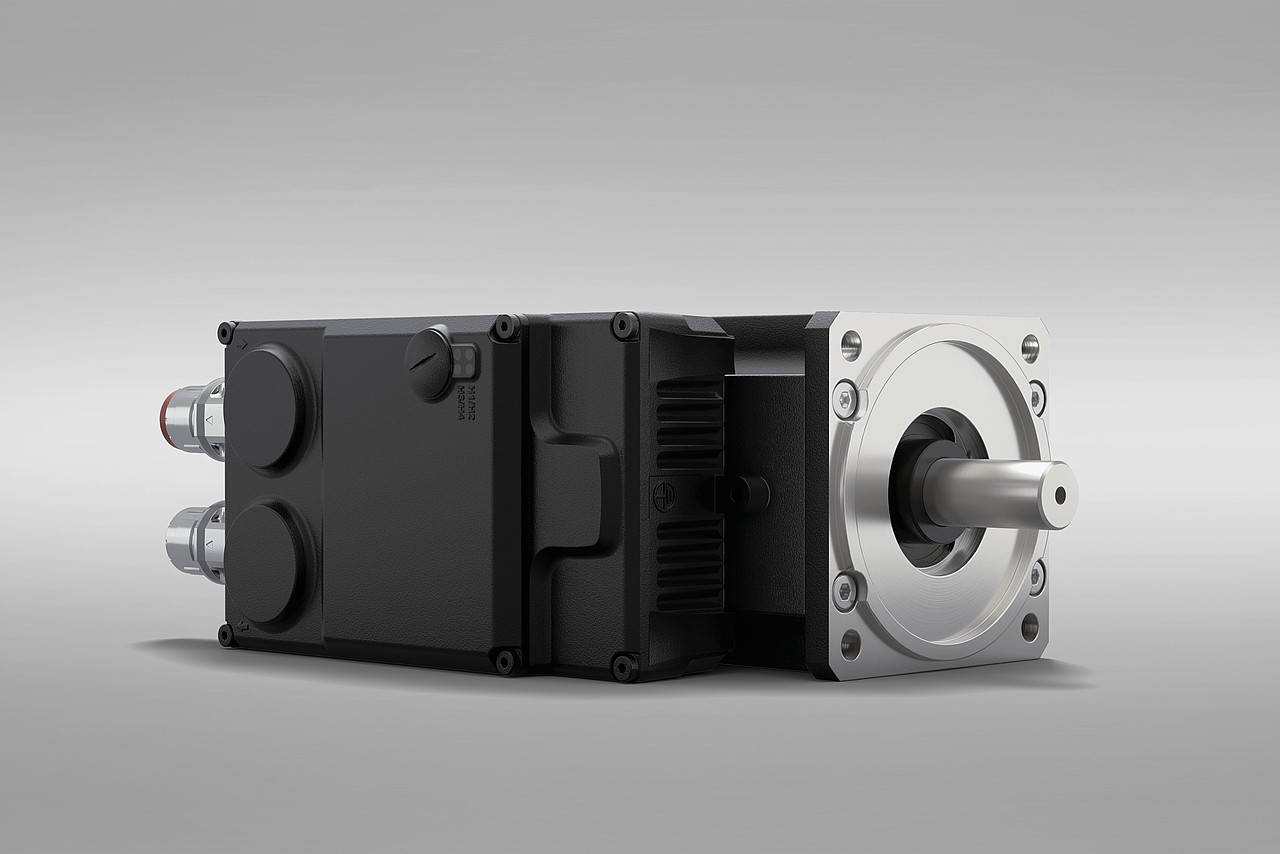

ihD-DT5

The synchronous servo motor with integrated inverter and hybrid cable connection

The synchronous servo motor with integrated inverter and hybrid cable connection

The distinctive feature of the decentralized ihD servo inverter is its hybrid cabling concept. A single cable transmits power, STO (Safe Torque Off), 24 volts and communication in equal measure, connecting all interlinked components using the daisy-chain method. This significantly reduces installation effort. Compared to a centralized concept, it saves up to 70 percent of cabling costs.

The ihD is available as a standalone version or mounted on the DT motor series as the ihD-DT5. It offers the user a wide range of power ratings and a high degree of flexibility: with a rated current of eight amps, even a triple overload does not push the device to its limits. This gives the user greater freedom and flexibility when it comes to designing drive axes. Thanks to its EMC-compatible aluminum housing, enhanced protection class IP65 and resistance to shock and vibration, even harsh operating conditions are not a particular challenge for the ihD.

The decentralized servo inverter ihD with hybrid cable connection offers a continuous output of 5kVA and has a triple overload capacity (for 1 second).

The special feature of the ihD servo inverter is its hybrid cabling concept. Power, STO (Safe Torque Off), 24V and fieldbus communication are connected via a single cable. These signals can also be connected to other decentralized drives via a daisy-chain system.

The integration of the control electronics on the servomotor significantly reduces the amount of cabling required. No external wiring is required between the motor and the electronics. The connections are routed internally.

Motor type | ihD5-DT5-3-10-xxO | ihD5-DT5-5-10-xxO | ihD5-DT5-9-10-xxO |

|---|---|---|---|

Flange size [mm] | 100 | 100 | 100 |

Maximum torque [Nm] | 11.1 | 20 | 31 |

Maximum current [Arms] | 20 | 24 | 24 |

Continuous stall torque [Nm] | 2.3 | 4.2 | 7.3 |

Continuous stall current [Arms] | 2.4 | 3.8 | 5 |

Rated torque [Nm] | 1.67 | 2.1 | 2.3 |

Rated current [Arms] | 1.8 | 2 | 1.7 |

Rated speed [rpm] | 3500 | 3500 | 3000 |

Rated power [W] | 600 | 760 | 710 |

Moment of inertia (without brake) [kgcm²] | 1.6 | 2.9 | 5.5 |

Motor length [mm] | 163.5 | 195 | 258 |

Motor length with brake [mm] | 191.5 | 233 | 286 |

Weight without brake [kg] | 4.5 | 5.7 | 8.7 |

Further variants and specifications of our decentralized servo inverter, with or without attached motor from the DT motor series, can be found in the technical data sheet.