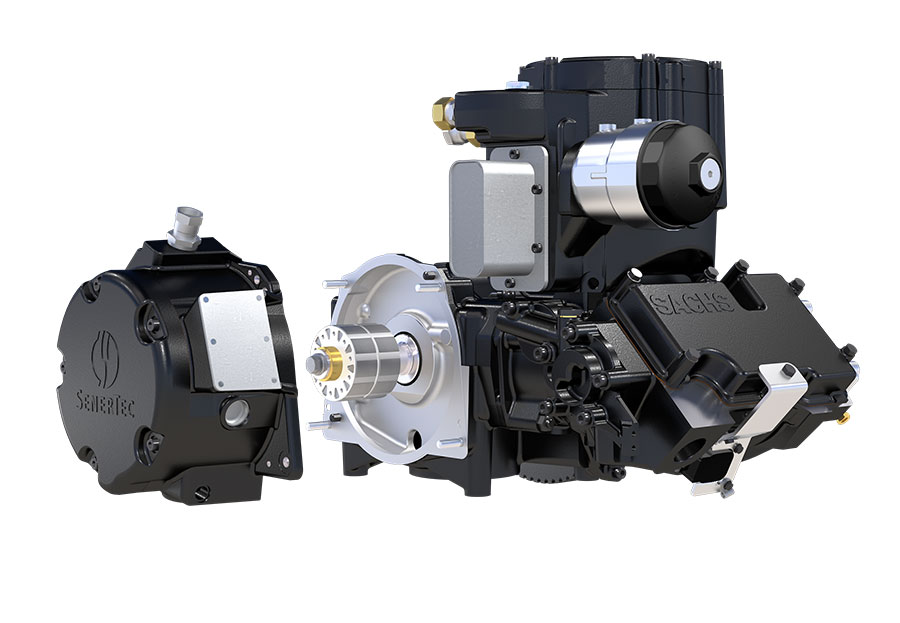

Synchronous generator for SenerTec’s Dachs

In the Dachs by SenerTec, a synchronous generator made by AMKmotion in conjunction with a frequency inverter now provides the voltage instead of the asynchronous generator.

In order to increase the efficiency of the Dachs combined heat and power plant, manufacturer SenerTec was looking for a new generator solution. The company found what it was looking for by consulting its long-standing technology partner AMKmotion.

A specially designed synchronous generator – flanged directly to the combustion engine and adapted to the requirements.

The water-cooled synchronous generator by AMKmotion in the Dachs has an output of seven kilowatts, offers 29 Newton metres of torque and has an efficiency of 95.5 percent.

In the new version of its Dachs combined heat and power unit (CHP), which has been consistently optimised for high efficiency, manufacturer SenerTec was looking to break new ground with the generator: instead of the asynchronous generator, a synchronous generator with frequency inverter was to provide flexibility in future. The solution was provided by technology partner AMKmotion: a special design flanged directly to the motor and adapted to the requirements.

SenerTec Kraft-Wärme-Energiesysteme GmbH is a mechanical engineering company founded in 1996 and based in Schweinfurt. Currently employing a workforce of around 25 employees, the products produced and marketed by the company currently include the Dachs mini CHP unit – one of the best-selling combined heat and power systems in Europe. “The Dachs originally goes back to Fichtel & Sachs,” says Roland Engert of the SenerTec Technology Centre. It was there that the Sachs heat pump – which was ready for series production – was further developed into a combined heat and power unit, today’s Dachs. The advantage: the heater was additionally able to generate electricity. The Sachs Energy Technology department then went on to become a company in its own right in 1996: SenerTec Kraft-Wärme-Energiesysteme GmbH. From then on, the Dachs was mass-produced and further developed on an ongoing basis.

“Even back then, the aim was to maximise efficiency,” explains Engert. “And AMKmotion supplied the generator at that time, too.” In the first-generation Dachs, an asynchronous generator for the specified motor output of 5.5 kW with an efficiency of 92 per cent fulfilled the rigorous requirements very well for more than 30 years. “SenerTec used the generator in the Dachs virtually unchanged over this long period. This says something about the quality and innovativeness of the technology used,” says Jürgen Kuch, Key Account Manager at AMKmotion. “Our asynchronous generator already had a copper rotor specially made in France, for example – a technology that has only become a must-have in recent years.”

But development doesn’t stop even when a system is well established. New standards and increasing digitalisation led SenerTec to take the decision to evolve the Dachs further – to create a second generation Dachs with the latest technology and even greater efficiency. “Efficiency, efficiency and efficiency – those were the goals we set for the second-generation Dachs,” says Roland Engert with a laugh.

The generator has a key role to play here. That’s why SenerTec wanted to install a synchronous generator with a frequency inverter in the second generation Dachs: it isn’t just variable in power and frequency, it is also used as a starting system for the combustion engine, so a starter is no longer necessary. In addition, the solution once again had to be extremely durable, designed to be able to withstand a high level of shock and vibration, and also be resistant to oil and exhaust fumes. With this plan, SenerTec turned to its long-standing technology partner AMKmotion very early on in the project phase.

“SenerTec came to us with the specifications and asked us the crucial question,” says Jürgen Kuch. “What can you do about this?” The Kirchheim-based company didn’t have anything suitable on the shelf, but they were able to offer a special customised solution based on an existing AMKmotion product. “We took on the task and got started with the development together with SenerTec. We would often get together to collect ideas and work on a solution,” says Kuch.

The result is a small masterpiece: a water-cooled synchronous generator with 29 Newton metres of torque, seven kilowatts of power and an efficiency rate of 95.5 percent. One particularly nice detail: the rotor is mounted directly on the crankshaft of the Dachs. “This eliminates a gear stage and the separate bearing. We were able to further increase the efficiency by a total of five per cent – and the solution is lighter and more compact, too,” says Engert. The lower weight in particular posed its own additional challenges, however. “As expected, it influenced the centre of gravity and the complete vibration decoupling of the unit,” adds Thomas Seufert, Team Leader for Purchasing and Supplier Support at SenerTec. “All that had to be completely re-analysed, calculated and re-dimensioned.”

The exemplary collaboration on an equal footing was a particular highlight for SenerTec on this project. “We’ve come a long way together,” says Roland Engert in summary. “We were open with each other at all times, always working constructively and on a solution-oriented basis.” The team also pulled together in the case of minor stumbles, such as when the rotor attachment that was originally planned with a shrink disc ultimately proved to be impractical. “We sat down at the table, analysed the problem together and then came up with a solution. And that’s how a project of this kind simply has to work,” says Seufert. The second-generation Dachs went into series production in 2018. Since then it has been used by numerous satisfied customers in the boiler room